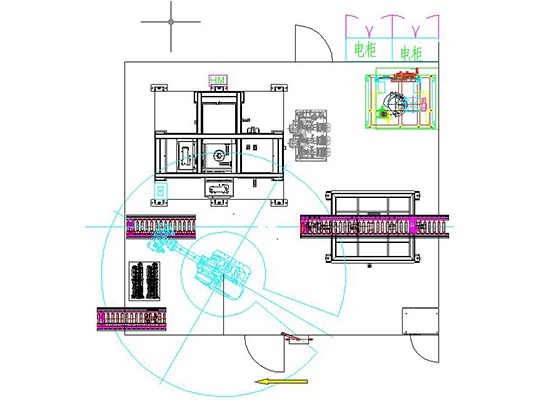

The engine auxiliary line auxiliary equipment mainly includes the cylinder cylinder head conveying line, the cylinder cylinder head oil channel water leakage test machine, the catheter seat plate press machine, the cylinder cylinder bowl bowl plug press machine, the camshaft tightening machine, the main bearing Cover tightening machine, simulation cylinder head removal and tightening machine, robot handle, marking machine and other components.

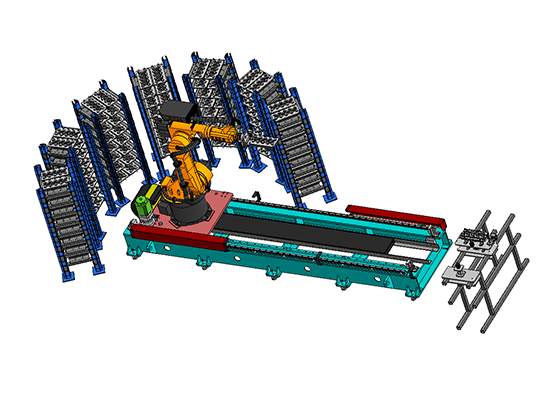

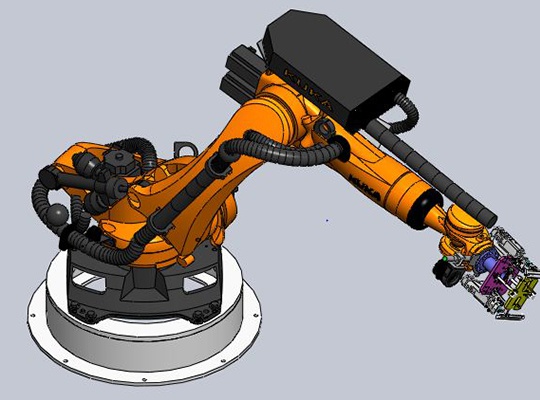

Combined with a variety of modular equipment and customized machine auxiliary process, including the cylinder, the cylinder head of the robot on the line, oil and water jacket leak test, bowl-like plug pressure, steel ball press, DCT, AT, CVT shell steel ball press, cavity leakage test, oil leak test and other core equipment, integrated robots, truss robots, the use of high- AGV / AGC intelligent logistics vehicles, flexible roller conveyor systems, to provide customers with production facilities performance, efficiency, flexible solutions and turnkey projects.

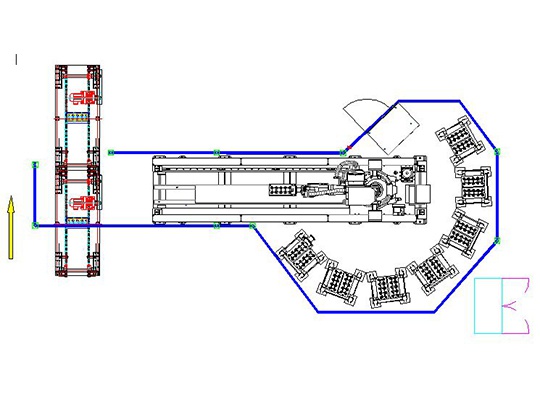

The truss manipulator has the characteristics of high speed, high precision and large coverage, and is suitable for the high speed of the machine.

The truss manipulator has the characteristics of high speed, high precision and large coverage, and is suitable for the high speed of the machine.

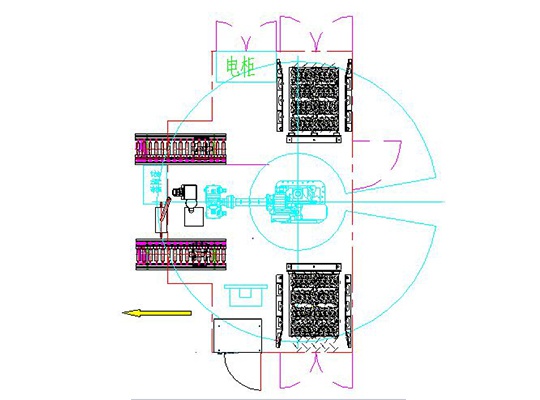

Robot working island way with high flexibility characteristics;

Robot working island way with high flexibility characteristics;

As a mature product, each part of the machine automation system has been subjected to long-term verification of rated load, life and reliability.

As a mature product, each part of the machine automation system has been subjected to long-term verification of rated load, life and reliability.

Cylinder head positioning pin

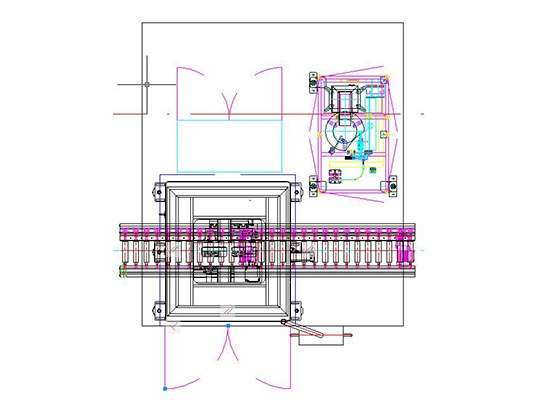

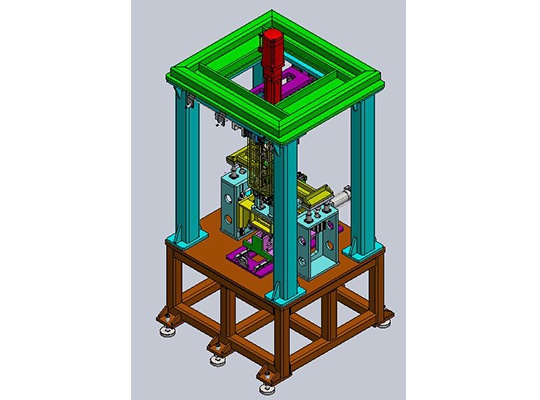

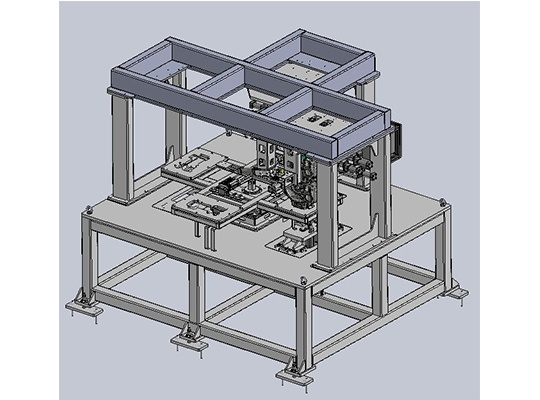

Cylinder head positioning pin press machine

Cylinder head blank on-line station

Cylinder head blank on the line hand

Simulation cylinder head library

Simulated cylinder head

Cylinder head waterway leak detection equipment

Cylinder head bowl-shaped plug coating and pressure test station

Cylinder head bowl type plug press machine

Cylinder head handle